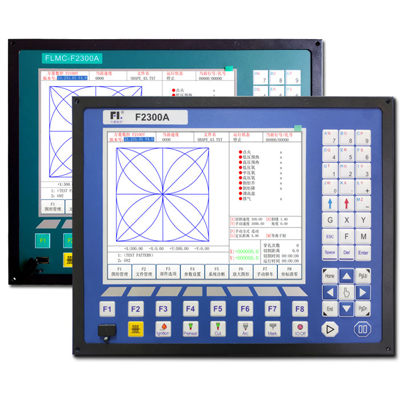

Control series

2Axis CNC Controller System F2300A for CNC Flame and CNC Plasma Cutting Machine

- Product ID:Control series

- QQ:1300198164

- Phone: +8618981381223

- Tel: +8618981381223

- Email: hmtechcnc@gmail.com

- Time: 2022-10-27 21:06:16

- FEEDBACK

It can be used in CNC flame cutting machine equipment and CNC plasma cutting machine equipment, CNC flame plasma dual-purpose cutting machine equipment.

Environmental requirements

The numerical control system is suitable for working at an ambient temperature of 0 ° C to 50 ° C, and a relative humidity of 5-95% without condensation.

The working voltage is DC +24V.

This controller should be installed in a console enclosure with protective dust.

This system is best used in places away from high-voltage high-frequency and high-radiation.

Attention:

Keep your hands and feet away from moving machines, control operations or manuals can be done through the front panel keyboard.

Do not wear loose clothing and clothing such as wire rope when operating the machine to prevent it from being caught by the machine.

This equipment should and should only be operated by trained personnel.

It is not a technician authorized by the company. It is strictly forbidden to dismantle the machine.

When using, do not splash acidic, alkaline, corrosive and other items on the control system.

High piezoelectric

Electric shock can hurt people to death. It must be installed in accordance with the steps and requirements of the packing parts.

When the power is turned on, you cannot touch the wires and cables.

This equipment should and should only be operated by trained personnel.

System Features:

Support language:Chinese, English, Spanish, Portuguese, French, Russian, Danish, Korean, Japanese and other language menus, one-click language switching.

- Support: metric-inch interconversion

- One-click switching.

- 47 common graphics libraries (including grid graphics) with the option to set the tile size and hole size.

- Support EIA code (G code) and FastCAM, FreeNest, SmartNest, IBE, etc.

- Nesting software. Supports suffixes TXT, CNC, NC, MPG, B3 and other G codes.

- Compact keyboard design for more comprehensive manual input

- Graphic scale, rotation, mirroring

- Graphics can be matrix arranged, interactively arranged, stacked

- The original size of the workpiece and the size of the slit are displayed simultaneously, which is intuitive and convenient.

- Graphic steel plate correction, any steel plate edge can be used as a correction edge

- Customizable coordinate system, supporting all eight possibilities for two-dimensional coordinates

- Customizable all input and output port types (normally open or normally closed) and numbered

- Self-diagnosis of all IO status and button status of the system for easy inspection and troubleshooting

- Front USB interface for easy program transfer

- The system upgrade adopts the U disk upgrade mode, which is convenient, simple and practical, and provides lifetime upgrade service.

- Support system backup and system restore function, system restore can restore only the operating system, can also be restored to Factory status.

- All functions and processes of the entire system can be upgraded online, eliminating the worry of after-sales

- Import and export processing files individually or all

- Parameter backup and parameter restoration

- Supports 4 modes of oxygen gas, plasma, dusting and demonstration

- Various processing parameters are available to meet different process requirements

- Oxygen gas and plasma IO are controlled separately

- Oxygen gas is automatically adjusted, two-stage preheating, three-stage perforation

- Plasma arc pressure feedback, positioning feedback, automatic closing of the arc voltage

- Built-in plasma arc pressure automatic / manual height adjustment function: can display the actual arc voltage and set the arc voltage, set the arc voltage

- Increase parameters, detect collision/positioning success signal, arcing signal control, positioning test

- Plasma arc pressure control supports both speed and distance to close the arc voltage height adjustment mode, making the machine tool more stable.

- Safety

- Support edge cutting, reduce warm-up time for thicker steel plates

- Accelerate and decelerate in real time during exercise

- According to the thickness of the steel plate, the speed limit can be automatically set at the corner to effectively prevent overburning.

- Manually select the starting line or select the perforation point

- Dynamic/static processing graphic display, graphic enlargement/reduction, dynamic tracking cutting point in zoomed state

- DSP high-speed, high-precision interpolation control, high-speed operation, stable operation, low noise

- Arbitrarily set the starting speed, lifting speed time

- With power-off, breakpoint protection memory function

- Offset cutting function avoids sheet waste due to incorrect counting calculations

- Different management rights and corresponding passwords can be set to maintain the rights of equipment manufacturers.

- Remote control that supports P2P mode or BCD (8421) mode

1.3 Technical Specifications

1) Number of control axes: 2-axis linkage (customizable three-axis)

2) Control accuracy: ±0.001mm

3) Coordinate range: ± 99999.99mm

4) Maximum pulse frequency: 250KHz; maximum operating speed: 15 meters / minute

5) Maximum number of program lines: 150,000 lines

6) Maximum single program: 4M

7) Time class resolution: 10ms

8) System working power: DC +24V DC power input, power is greater than 80W.

9) System working environment: temperature -10 ° C to +60 ° C; relative humidity 0-95% without condensation

10) Drive arc voltage increase motor maximum power: 45W (Note: only with T system)

1.4 System Interface

a) 15-core male two-axis motor drive interface

b) 16-core female 16-channel opto-isolated output, maximum sink current 300mA

c) 25-core male 16-channel opto-isolated input, maximum input current 300mA

d) The front panel has a built-in USB interface for the user to transfer the cutting code

e) extended IO input and output port; PWM input port; analog input port

The following interfaces, the F2000 series CNC system with "T" are available:

f) Arc voltage input divider ratio selection can be selected 1:50 or 1:100

g) 5-core arc voltage boost motor output and limit input

h) 7-core arc voltage and positioning input, arcing signal output port

1.5 Hardware Configuration

1.5.1 F2100B/T Hardware Configuration

1. Display: 7 inch 800*480 high resolution 16 million color high brightness LCD screen

2. Memory: 64M SDRAM

3. User program space: 256M

4. Main frequency: 400MHZ system frequency

5. USB: USB1.1 interface front, at least 16GB USB flash drive

6. Keyboard: PCB foil keyboard

7. Chassis: The whole steel structure is completely shielded, which can truly prevent electromagnetic radiation, anti-interference and anti-static

The details of the CNC system are as follows:

1pcs F2300A system

1pcs 25 core hole input plug (including sheath)

1pcs 25-pin needle output plug (with sheath)

1pcs 15-pin pin motor plug (with sheath)

1pcs 3P terminal power plug

1pcs Manual (Chinese)

CATEGORIES

LATEST NEWS

CONTACT US

QQ: 1300198164

Phone: +8618981381223

Tel: +8618981381223

Email: 1300198164

Add: Kehua North Road, Wuhou District, Chengdu City,Sichuan province,China